The largest and most experienced waterjet cutting service in Colorado

Since 1997, Colorado WaterJet has provided abrasive waterjet cutting services that help manufacturers simplify production. From aerospace, medical, automotive, energy, oil & gas and more, our team delivers custom parts that fit your specs, schedule, and budget. No headaches. No unnecessary delays.

Our Capabilities

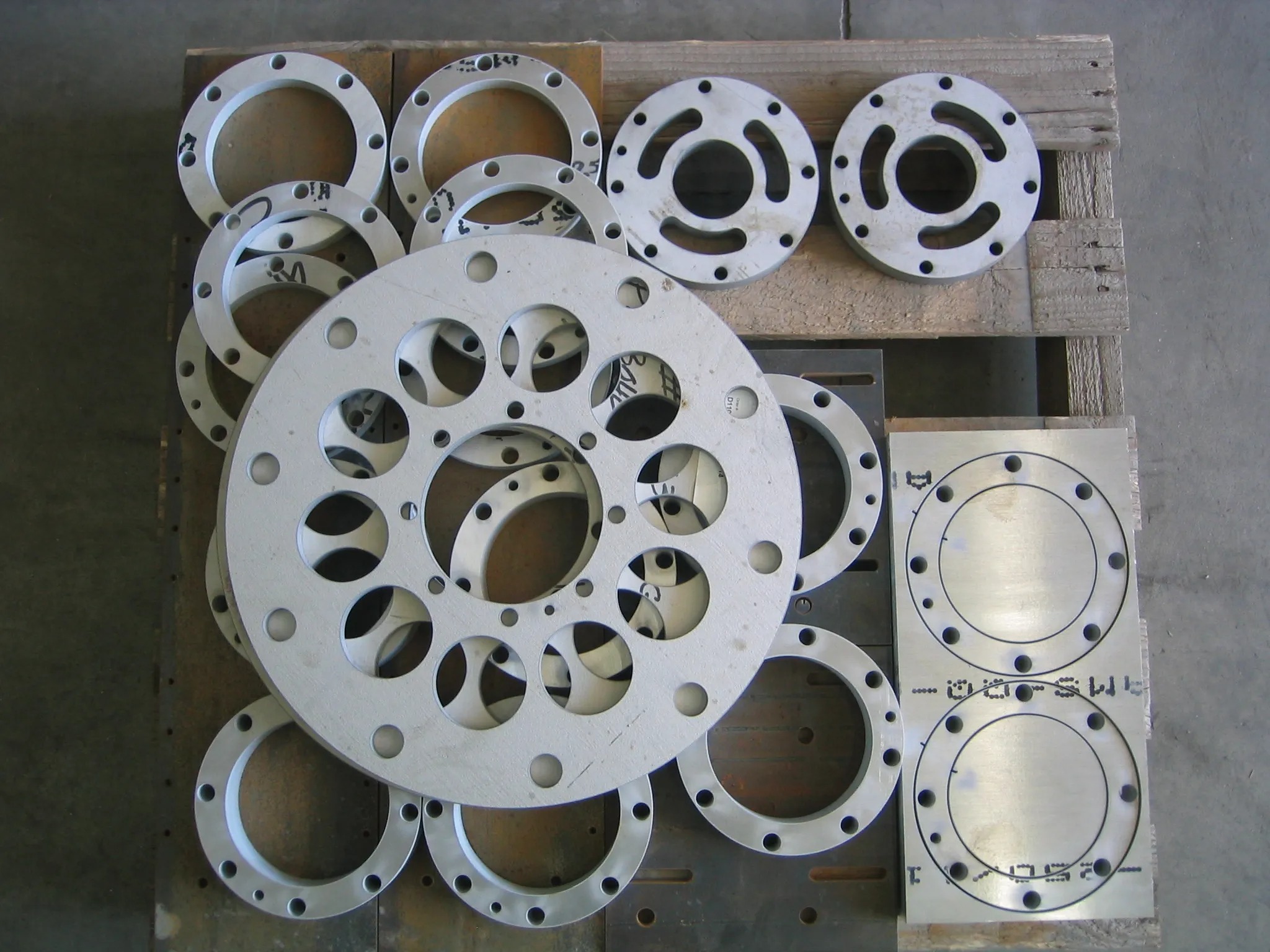

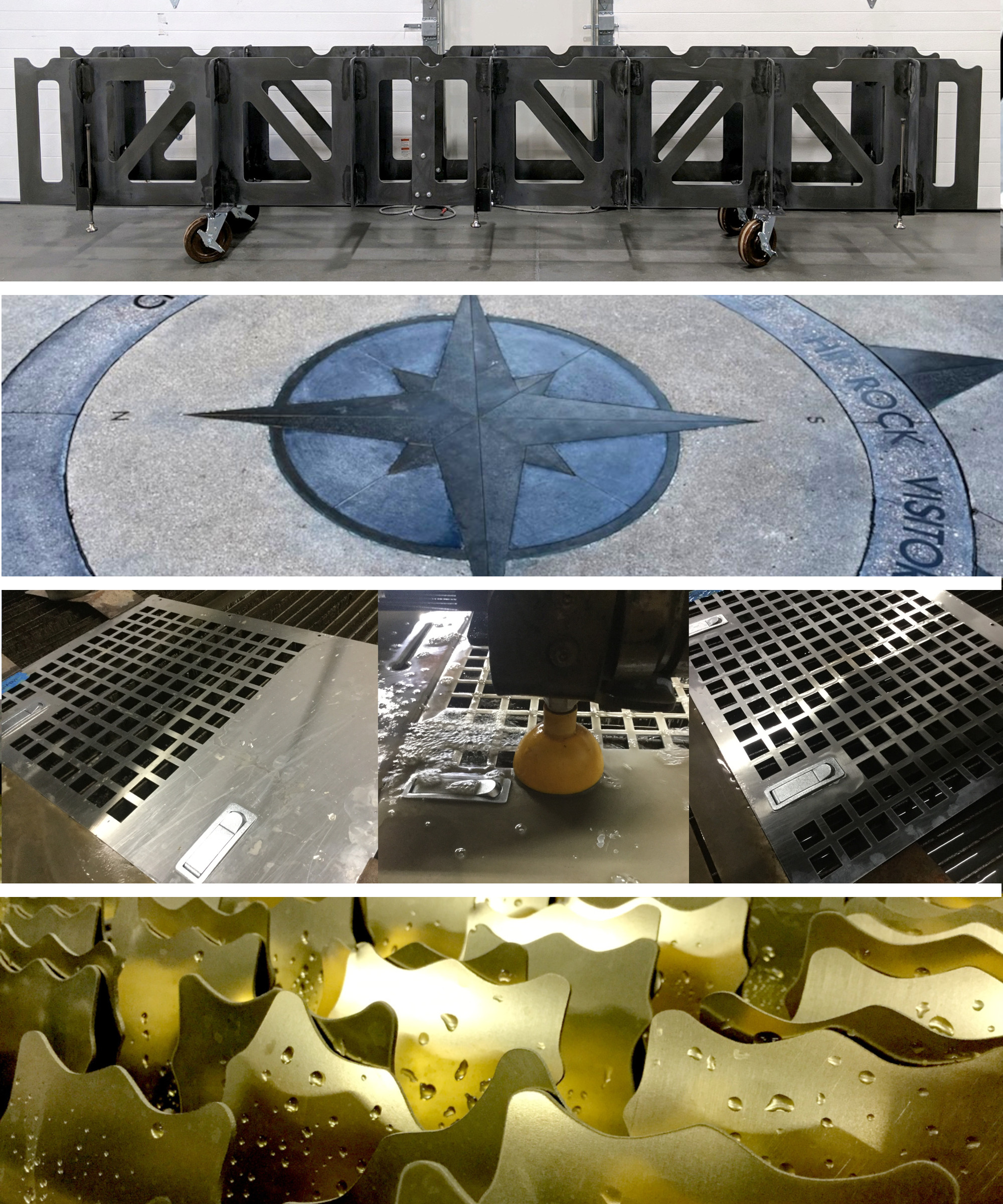

Our experienced team cuts everything from titanium bodies to layered composite material on our three large-format waterjet systems. From thick plate to paper thin material, large to small, prototype to production runs, single or layered, we deliver clean edges, tight tolerances, and fast turnarounds.

-

Broad Range of Materials: We routinely cut aluminum, stainless steel, carbon steel, titanium, Inconel, G10, phenolics, and multi-layered materials.

-

Certifications: We’re ITAR Registered, maintain a robust internal Quality Management System (QMS) and pass audits from ISO-driven customers.

-

Precision Results:

-

Max material thickness: hard materials up to 8″, softer materials up to 12”.

-

Min material thickness: .001”

-

Standard tolerance: ±0.005″

-

Drill attachment for composite materials to avoid delamination

-

Bevel cutting: up to 45° angle using 5th-axis waterjet head

-

-

Fast Turnaround: Standard 2-week delivery with 1, 3, and 5-day expedited options

-

Prototype to Production: Low-volume one-offs or high-volume nested runs

-

Advanced Techniques: We have extensive experience with part fixturing and secondary operation cutting.

-

Special Projects: 3D enclosures, bevel cuts, and composite cutting

Materials

Waterjets can cut just about anything, including most metals, plastics, wood and composites, including titanium, carbon fiber, UHMW, and laminates. We also handle rubber, foam, and stone-based materials.

Waterjet cutting produces clean, sand-blasted edges without heat, making it ideal for materials that melt, produce slag, or cause a Heat-Affected-Zone (HAZ) with high temperatures of other cutting methods.

Industries

We work with manufacturers across demanding sectors, including Manufacturing, Transportation, Machine Shops, Medical, Automotive, Oil & Gas, Renewable Energy, Retail, Commercial Signage, Construction, Architectural Engineering, Public Art, Telecommunications, Municipalities and our precision cutting services meet the expectations of regulated industries like Aerospace, Space Exploration and Defense.

Frequently Asked Questions

What is waterjet cutting?

The abrasive waterjet process works by cutting metal or other materials using a focused stream of highly pressurized water mixed with abrasive aggregate. The cutting head is Computer Numerically Controlled (CNC), achieving a precision of ±0.003″ per side.

High-pressure water hits the material at three times the speed of sound, carrying fine garnet abrasive in the stream with it. This combination of water and garnet cleanly erodes the material without transferring any heat into the process.

What materials can you cut?

We cut most metals, plastics, and composites, including titanium, carbon fiber, UHMW, and laminates. We also handle rubber, foam, and stone-based materials.

Waterjet cutting is generally not used for tempered glass.

[See full list on our Materials page]

What is your typical turnaround time?

Our standard turnaround time is 2 weeks for most jobs. If you’re working on a tight deadline, we also offer 1-day, 3-day, and 5-day expedited options depending on scope.

Do you offer expedited services?

Yes. Our standard turnaround is 2 weeks, but we offer 1-day, 3-day, and 5-day expedited options for projects that need to move fast.

Can I supply my own material?

Yes. We frequently cut customer-supplied materials with isolated traceability.

Ready to Get Started?

Request a quote or contact our team to talk through your project. We’ll respond quickly with details you need to keep production moving.